Audio (Richard Pittard): A lot of people talk about circularity and circular business models, but there's very few that actually exist.

Video: Richard Pittard speaks to the camera.

Audio (Richard Pittard): We realised at Australia Post that we had a unique opportunity to enable circularity in Australia, but we can't do it alone. The circularity proof of concept is a way of getting all of the value chain actors together and actually translating something from theory into practice. Let's see if we can make a circular business model stand up.

Video: Footage of the Australia Post building and a group of people mingling.

Audio (Marty Rowell): 220,000 tonnes of textiles end up in landfill every year.

Video: Marty Rowell speaks to the camera.

Audio (Marty Rowell): It's a significant problem that touches the whole population. It was a natural place to start.

Video: People smiling and talking to each other at an event.

Audio (Marty Rowell): Obviously, as Australia Post we support our customers in delivering clothing and apparel. What we're now looking to do is extend that to customers, to be able to return those items once they’re finished with them, and then to be able to close the loop and really address how we can minimise the number of products going to landfill and actually improve that customer experience as well.

Video: Parcels being placed on a conveyor belt and moving through a facility.

Audio (Megan Priest): For a consumer, they're shopping on our website, they get to the checkout, and there's a pop-up and an offer to the customer: Recycle with R.M. Williams.

Video: Megan Priest speaks to the camera.

Audio (Megan Priest): From there, this is intended to be maybe an R.M. Williams’ piece that they’ve had and loved and worn for many, many years, and it's come to the end of its life. So now with this proposed solution, they'll be able to receive a satchel from us directly with their next order.

Video: People smiling and talking to each other at an event and looking at garments on display.

Audio (Samantha Yap): With customer lodgement, the customer is going to get the satchel when they receive some freight.

Video: Samantha Yap speaks to the camera.

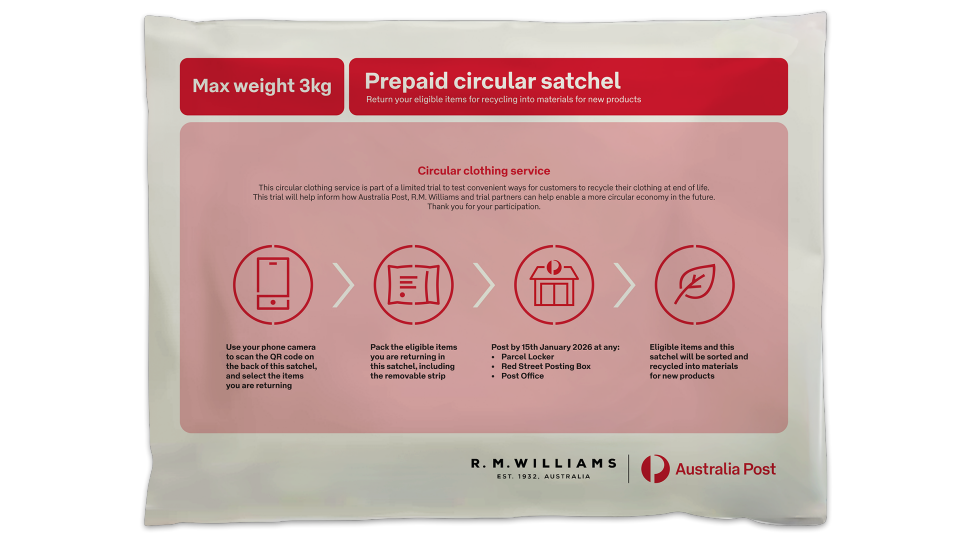

Audio (Samantha Yap): They're going to look in their closet or hopefully they've got something lying around that they do want to recycle and they're going to pop it in the satchel. From that point in time, they will scan a QR code. They'll pop their stuff in and on that QR code, they'll be taken to the Australia Post App where they can choose their lodgement.

Video: People demonstrating how to use your phone to lodge a parcel.

Audio (Charlene Fernando): Once the customer has lodged their articles digitally, we’ll either collect them from your home depending on the option you’ve chosen, which is a future state option, or we’ll collect them from a parcel locker, and they'll be processed through our facilities and proceed to the next step in our journey.

Video: Charlene Fernando speaks to the camera.

Video: Person demonstrating how to use your phone to track a parcel. A facility in operation.

Audio (Charlene Fernando): We want sustainability to be embedded at every stage of the journey. In terms of the packaging, we're looking at making them 100% recyclable.

Video: Charlene Fernando speaks to the camera.

Audio (Nathan Radley): When a satchel arrives at Remondis, essentially, we're doing a sorting and verification process.

Video: Nathan Radley speaks to the camera.

Audio (Nathan Radley): Our process is basically to quickly open and sort the package, identify any contamination and send the material off to its destination as quickly and efficiently as possible.

Video: A person holding and looking at a satchel and talking to other people.

Audio (Adrian Jones): We will receive the material from Remondis, and then it will be re-sorted into the fibre type and then shredded.

Video: Adrian Jones speaks to the camera.

Audio (Adrian Jones): It arrives at our plant where, through a chemical process, we’ll separate it into its building blocks of polyester and cellulose. The polyester can be converted back into textiles, so it can go back into clothing, and the cellulose will always go back into a hydro-mulch.

Video: An iPad displaying footage of material being shredded at a facility.

Video: People smiling and talking to each other at an event.

Video: Marty Rowell speaks to the camera.

Audio (Marty Rowell): From here, we'll continue to work with the brands. We'll look at how we can extend this from just a proof of concept into a real-life pilot.

Video: People smiling and talking to each other at an event.

Audio (Richard Pittard): There's been some really unique learnings through this process.

Video: Richard Pittard speaks to the camera.

Audio (Richard Pittard): I'm really excited for putting those learnings into practice and to stand up a truly circular business model in Australia. This is all about collaboration and innovation at its best. It's about Australia Post helping its customers to deliver circular solutions and to create value for all Australians. This is about delivering for the future.

Video: People smiling and talking to each other at an event.

Audio (Richard Pittard): This is about delivering for the future.

Video: Richard Pittard speaks to the camera.