About us

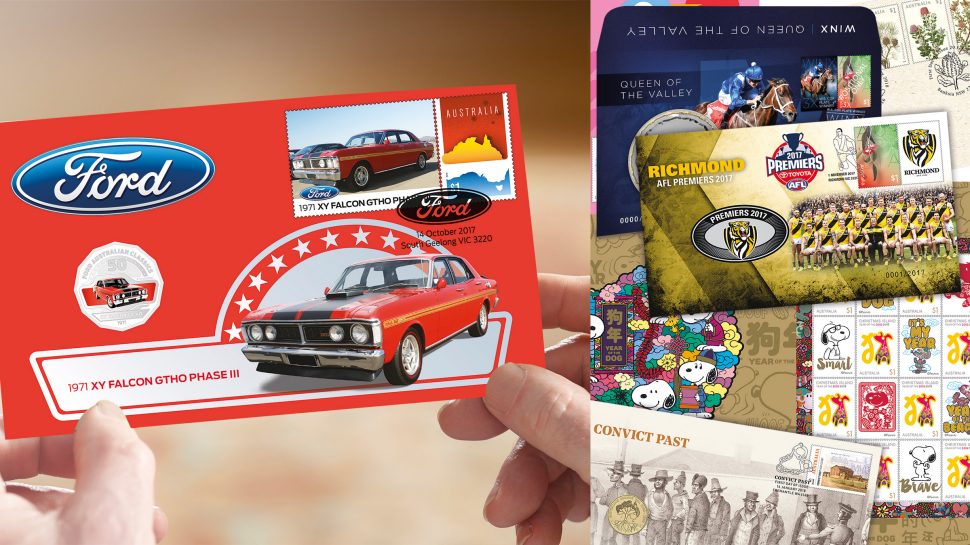

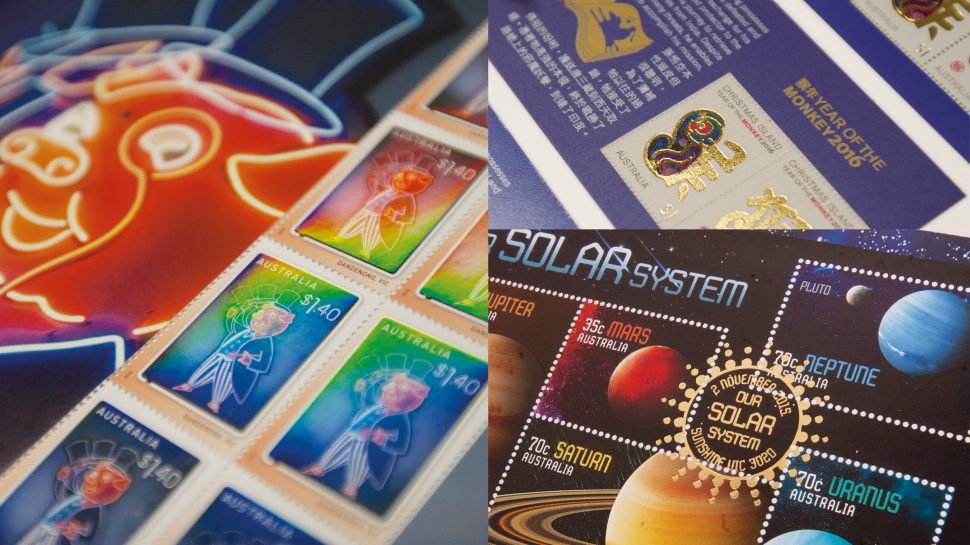

Australia Post Sprintpak is a supplier of self-adhesive dispenser roll and booklet stamps, gummed stamps and related philatelic product such as stamp albums, FDCs, postmarking, stamp packs, retail and collectables packaging.

Since our inception in 1970, we have produced a range of coin, numismatic and stamp collectable and souvenir packed product for Australia Post, US Federal Reserve Bank, the State of Kuwait, Bank of Japan, National Bank of Romania, Bank of Papua New Guinea, Central Bank of Sri Lanka and Note Printing Australia.

We have received over 30 excellence medals from the Australian National Print Awards, and have SAI Global ISO 9001 2008 quality assurance certification.

Our facility is wholly owned by Australia Post. As such, all of our production processes are carried out in secure sites, on state-of-the-art equipment designed to comply with the requirements of Australia Post.

We provide the full range of services from research, product development and innovative design through to manufacture and delivery of stamp packaging and product solutions.

With our wealth of product expertise, Australia Post Sprintpak has the complete supply solution, from design stage through to delivery to your door.